Precision that Sets the Standard in Oil and Gas Manufacturing

We manufacture parts and products for oil rigs, oilfield drilling systems, gas turbines, steam turbines, downhole hardware, and more.

Engineered to Withstand Harsh Environments

From start to finish, all of our manufacturing processes are planned and controlled under a documented Quality System designed to assure all services and products meet or exceed your order requirements and expectations.

Below is a list of the common materials we use:

Stainless Steels

- 300/400 Series

- 15-5PH

- 17-4PH

- Nitronic 40/50/60

Steel

- 4140

Superalloys

- A-286

- Invar

- Kovar

- Inconel

- Monel

- Titanium

Our Success Stories

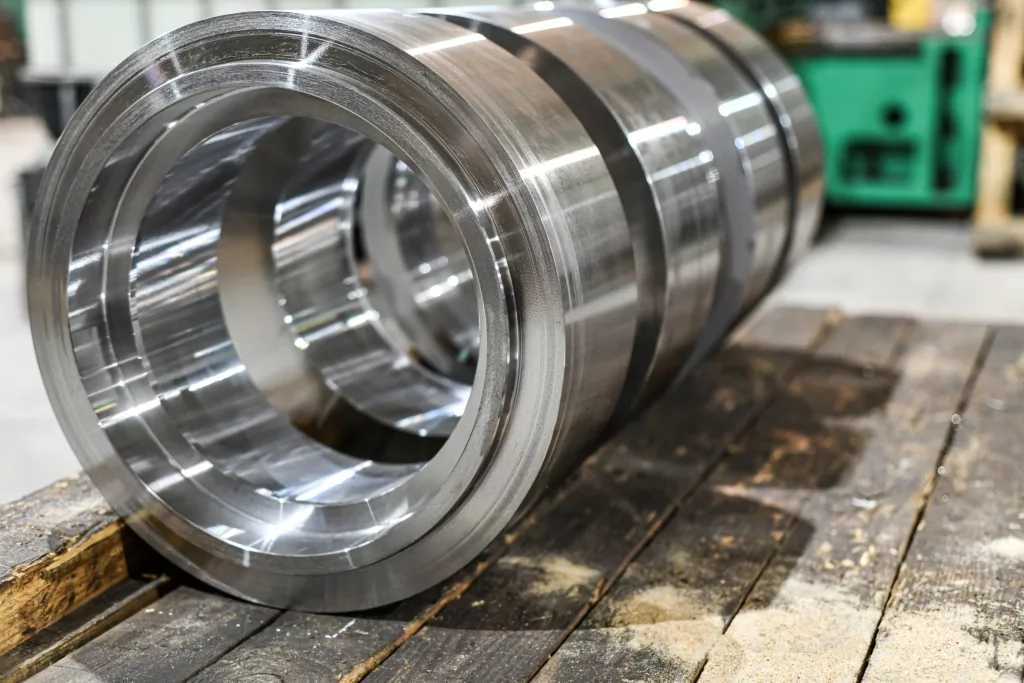

Heavy lifting

The oil and gas industry are still an integral part of everyday life. Tight turn arounds of large steel components are necessary to compete with the demand. Safety is of the primary concern, production through-put the other. Organizing the multiple operations and heat treatment needs of this modern-day industry takes strength and fortitude to accomplish.

Driven to succeed

With the combination of safe rigging, material moving equipment/procedure and high efficiency machining (HEM) toolpaths, we’ve been able to drive home these projects. Using proprietary tooling has been the name of the game to increase our effectiveness; producing sophisticated trochoidal toolpaths to cut costs and prolong tool life has been a boon to us and our customers, adding value and enriching the end-product.

Speak with Our Experts

Let’s explore ways to enhance your procurement processes, optimize inventory management, fine-tune your product offerings, and drive down expenses.

We’re Ready to Tackle Your Most Challenging Projects

Explore our work in the Oil and Gas industry.